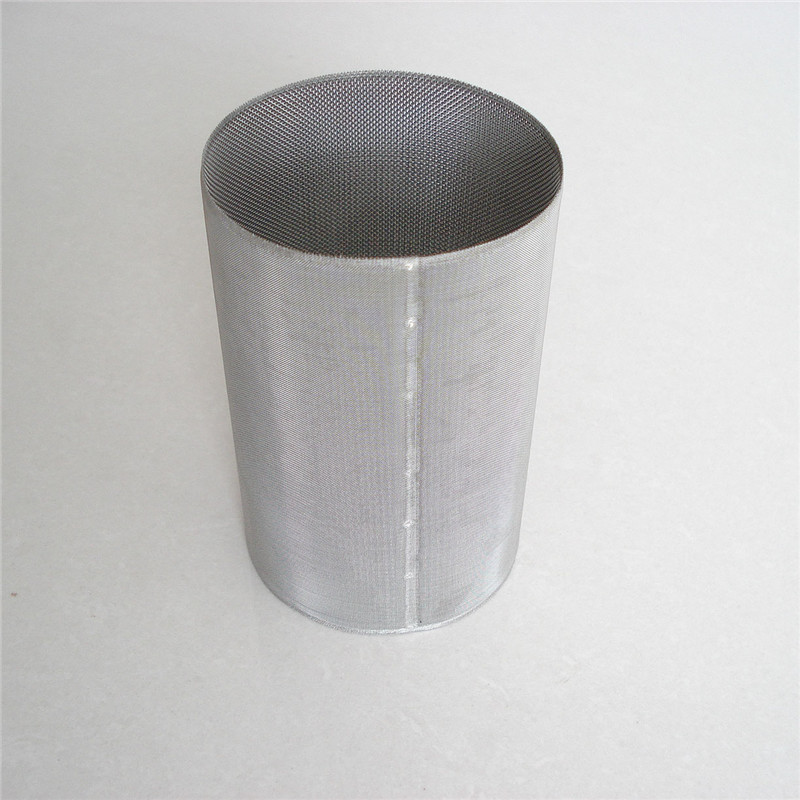

Industrial Liquid Filteration of 304/316 Stainless Steel Basket Filter Element

They consist of filter housings, filter elements supported by perforated cages, and positive sealing arrangements to avoid any bypass and optional end connections.

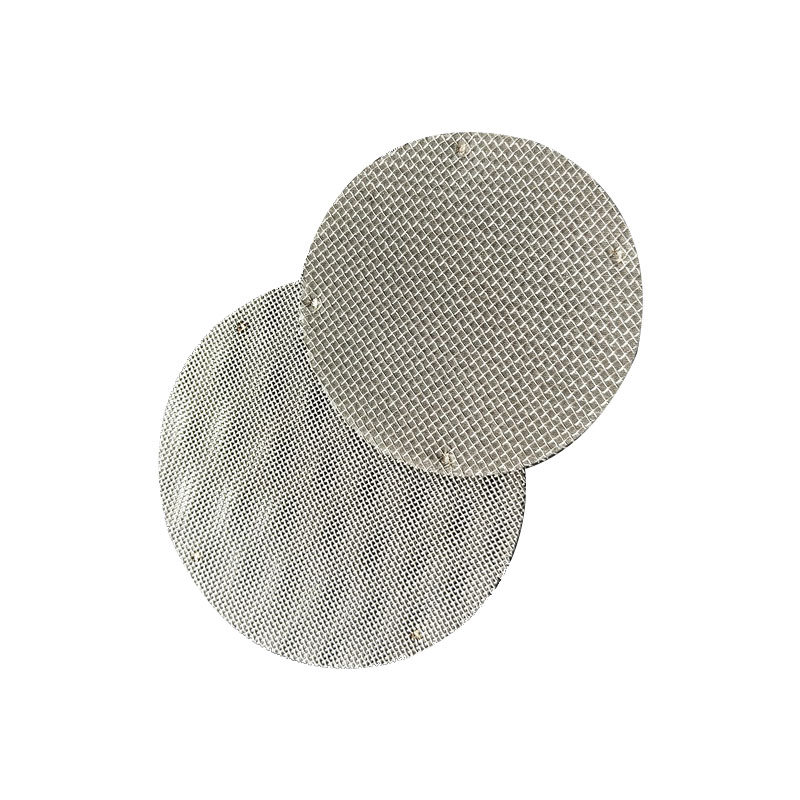

Filter material: basket filter filter material includes stainless steel perforated sheet, stainless steel woven mesh and stainless steel sintered silk cloth. In terms of overall dimension and filter grade, we can also provide products according to customers' requirements.

Application: basket filter is mainly used in petroleum, chemical industry, food, beverage, water treatment and other industries.

Operation: unfiltered liquid enters and passes through the basket shell. According to the design, solids are contained inside / outside the basket and removed during equipment maintenance. They have in-situ backwashing devices and usually do not need to remove the cleaning basket.

Basket filters are usually equipped with a spring device on the top of the filter element. This will ensure the location of any type of bypass and confirmation basket, even in the case of countercurrent. An optional O-ring seal between the rim and the inside diameter of the housing prevents fluid bypass around the rim.

Features and advantages

Large area, heavy basket.

Low pressure drop.

Houses are permanent pipes.

The bonnet is sealed with O-rings.

Carbon steel or stainless steel (304 or 316) housing.

Easy to clean.

Selection of local backwashing.

The filtration grade can range from 5 microns to 2000 microns and above.

Double basket filter

ASME code stamp.

High voltage rated design is available.

The flow reaches 2000 m3 / h.

Custom design services.

All enclosures are made of stainless steel 316L, stainless steel 316 and SS304 mirror polished to resist the adhesion of dirt and scale.

The carbon steel shell is sand blasted and coated with epoxy resin, and finally coated with two layers of synthetic enamel.

Easier to maintain liquid displacer.

Double / triple cylinder and jacketed units are available.

High temperature and high pressure design is available.

It is usually designed as the free flow area through the screen, which is 4 - 6 times the flow area of the pipeline.

Selection of basket filter element

Single cylinder design.

Double cylinder design.

Multi cylinder design.

The foldable element design is suitable for low pressure drop and high dirt retention.